Ualloy Anneal Bright&Soft Resistance Wire 0cr25al5

Basic Info

Model No.: 0cr25al5

Product Description

Model NO.: 0cr25al5 Material: Fecral Resistivity: 1.42 Density: 7.1 Trademark: UALLOY Specification: ISO9001, ISO14001 HS Code: 72209000 Product Type: Strip Carbon Content: Low Carbon Hb: 200-260 Width: 5-12mm Transport Package: Wooden Case, Wooden Pallet Origin: China Fecral Heating 0cr25al5 Alloy

1. Introduction

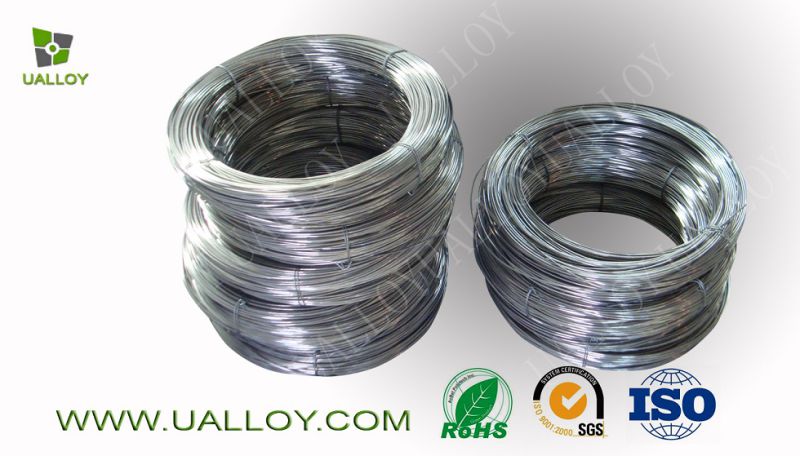

With the characteristics of high resistance, low coefficient of electric resistance,

High operating temperature, good corrosion resistance under high temperature.

It is mainly used in electric ceramic cooktop, industrial furnace.

2. Features

Stable performance; Anti-oxidation; Corrosion resistance; High temperature stability; Excellent coil-forming ability; Uniform and beautiful surface condition without spots.

3. Specification

3.1. Electric ceramic cooktop resistance strip:

Thickness: 0.04mm-1.0mm

Width: 5mm-12mm

Thickness&Width: (0.04mm-1.0mm)× 12mm(above)

3.2. Low resistance ribbon:

Thickness&Width: (0.2mm-1.5mm)*5mm

3.3. Industrial furnace ribbon:

Thickness: 1.5mm-3.0mm

Width: 10mm-30mm

Contact us if you need more details on Fecral Heating Resistor Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about 0cr25al5 Heating Resistance Wire、Resistance Heating Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Introduction

With the characteristics of high resistance, low coefficient of electric resistance,

High operating temperature, good corrosion resistance under high temperature.

It is mainly used in electric ceramic cooktop, industrial furnace.

2. Features

Stable performance; Anti-oxidation; Corrosion resistance; High temperature stability; Excellent coil-forming ability; Uniform and beautiful surface condition without spots.

3. Specification

3.1. Electric ceramic cooktop resistance strip:

Thickness: 0.04mm-1.0mm

Width: 5mm-12mm

Thickness&Width: (0.04mm-1.0mm)× 12mm(above)

3.2. Low resistance ribbon:

Thickness&Width: (0.2mm-1.5mm)*5mm

3.3. Industrial furnace ribbon:

Thickness: 1.5mm-3.0mm

Width: 10mm-30mm

| The allowable tolerance of alloy wire and rod diameter GB/T1234-2102 | ||

| Category | Diameter(mm) | Tolerance(mm) |

| Cold-drawn steel wire | 0.02 ~ 0.025 | 0.02 ~ 0.025 |

| 0.025 ~ 0.03 | 0.025 ~ 0.03 | |

| 0.03 ~ 0.05 | 0.03 ~ 0.05 | |

| 0.05 ~ 0.1 | 0.05 ~ 0.1 | |

| 0.1 ~ 0.3 | 0.1 ~ 0.3 | |

| 0.3 ~ 0.5 | 0.3 ~ 0.5 | |

| 0.5 ~ 1.0 | 0.5 ~ 1.0 | |

| 1.0 ~ 3.0 | 1.0 ~ 3.0 | |

| 3.0 ~ 6.0 | 3.0 ~ 6.0 | |

| 6.0 ~ 8.0 | 6.0 ~ 8.0 | |

| 8.0 ~ 10.0 | 8.0 ~ 10.0 | |

| Hot-finished rod | 5.5 ~ 12.0 | ±0.4 |

| The allowable tolerance of alloy strip GB/T1234-2012 | ||||

| Category | Width ( mm ) | Tolerance ( mm ) | ||

| side cut | Nonside cut | |||

| Common precision | High precision | |||

| Cold-rolled Strip | 5.0 ~ 10.0 | ±0.2 | ±0.1 | -0.6 |

| 10.0 ~ 20.0 | -0.8 | |||

| 20.0 ~ 30.0 | -1 | |||

| 30.0 ~ 50.0 | ±0.3 | ±0.15 | -1.2 | |

| 50.0 ~ 100.0 | ±1.0 | |||

| 100.0 ~ 200.0 | ±0.5 | ±0.25 | ±1.5 | |

| 200.0 ~ 300.0 | ±1.8 | |||

| Hot-rolled Strip | 15.0 ~ 60.0 | / | ±1.5 | |

| 60.0 ~ 200.0 | ±2.5 | |||

| 200.0 ~ 300.0 | ±3.0 | |||

| The allowable tolerance of alloy strip GB/T1234-2012 | |||

| Category | Thickness ( mm ) | Tolerance ( mm) | |

| Common precision | High precision | ||

| Cold-rolled strip | 0.05 ~ 0.1 | ±0.01 | ±0.005 |

| 0.1 ~ 0.2 | ±0.015 | ±0.01 | |

| 0.2 ~ 0.5 | ±0.02 | ±0.015 | |

| 0.5 ~ 1.0 | ±0.03 | ±0.025 | |

| 1.0 ~ 1.8 | ±0.04 | ±0.03 | |

| 1.8 ~ 2.5 | ±0.05 | ±0.04 | |

| 2.5 ~ 4.0 | ±0.06 | ±0.05 | |

| Hot-rolled Strip | 2.5 ~ 5.0 | ±0.25 | ±0.2 |

| 5.0 ~ 7.0 | ±0.3 | ±0.25 | |

| 7.0 ~ 10.0 | ±0.4 | ±0.35 | |

| 10.0 ~ 20.0 | ±0.5 | ±0.45 | |

| Properties/Grade | MWS-875 | |

| Main Chemical composition(%) | Cr | 22.5 |

| Al | 5.5 | |

| Fe | Bal | |

| Tensile Strength(Psi at 20C) | Min | 105 |

| Max | 175 | |

| Resistivity at 20oC (μ Ω @ m) | Ohms/Cmf | 875 |

| Tcr 0-100C | 0.00002 | |

| Density (g/cm3) | 7.1 | |

| Pounds percubic inch | 0.256 | |

| Coefficient of linear expansion between20-100C(α × 10-6/oC) | 12 | |

| Melting point (approx. )( oC) | 1520 | |

| Magnetic attraction | Strong | |

Product Categories : FeCrAl Alloy

Premium Related Products

Other Products

Hot Products

Fesib Alloy Strip as Transformer Iron CoreThermal Spray Alloy Wire-Nial 95/5 (1.6mm, 2.0mm)Top Quality Type K Thermocouple WireStainless Steel Strip0cr25al5 Resistance Strip/Fecral Heating AlloyGood quality hollow copper rivet factory supplyChinese Fabrication Services turning partsSilver alloy wiresBrass copper strips factory supplySilver brass clad metal stripsSilver copper electrical contactslead frame material C7025copper alloy foilbrass name platenickel silver platebronze alloy properties